When you’re choosing an industrial gearbox, you might not realize just how many critical features can influence performance and reliability. You’ll want to pay close attention to torque capacity, gear ratios, and the materials used in construction. These factors can significantly affect the efficiency and longevity of your machinery. Additionally, maintenance needs and the size and weight of the gearbox are just as crucial. So, what should you prioritize to ensure optimal operation? The answer might surprise you as you explore these essential features further.

Torque Capacity

When it comes to industrial gearboxes, torque capacity is crucial for ensuring your machinery operates efficiently.

You need to understand that torque capacity refers to the maximum amount of rotational force a gearbox can handle. If you exceed this limit, you risk damaging not only the gearbox but potentially the entire system.

When selecting a gearbox, consider the specific requirements of your application. Think about the load you’ll be working with and how that translates into torque.

You’ll want a gearbox that can handle peak loads without faltering. It’s also important to factor in safety margins; having a little extra capacity can save you headaches down the line.

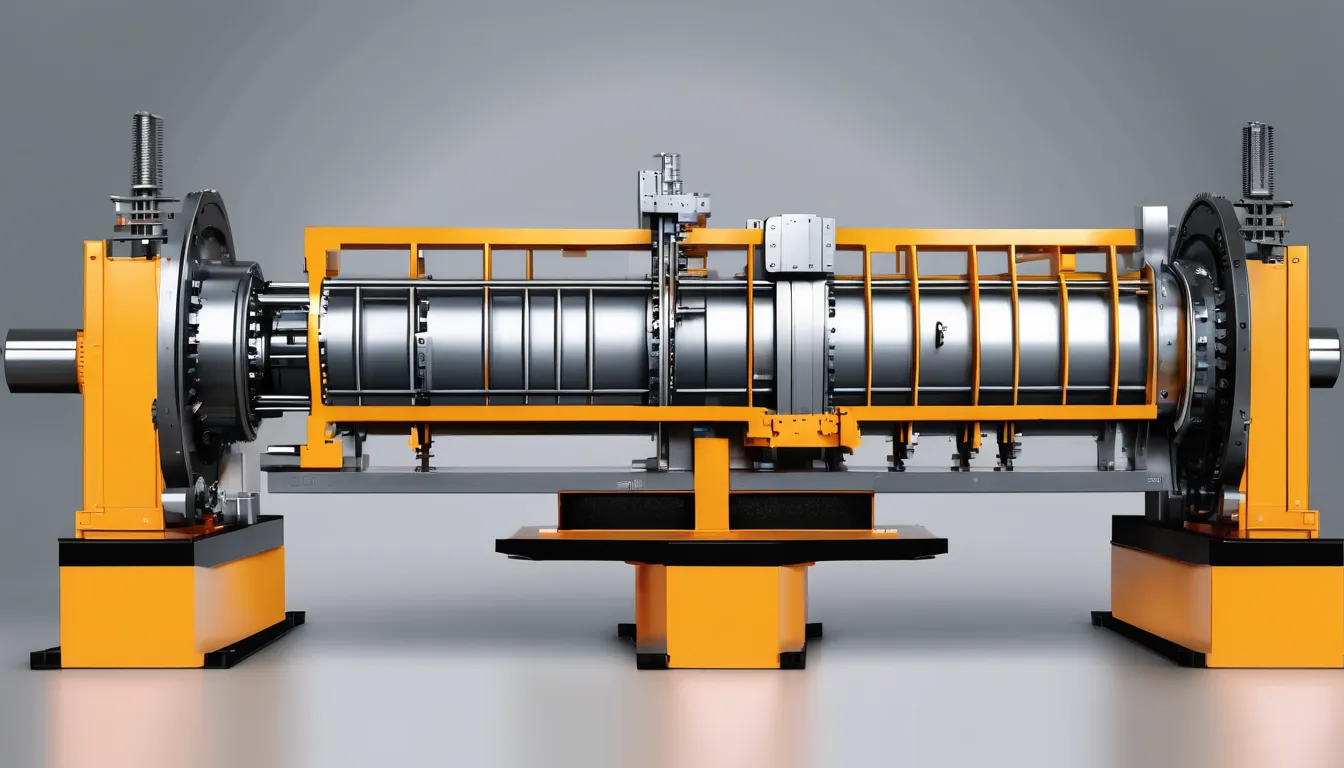

Additionally, look for features that enhance torque capacity, such as robust materials and efficient design.

High-quality gears and bearings can significantly increase the torque that your gearbox can manage.

Gear Ratios

Understanding gear ratios is essential for optimizing the performance of your industrial gearbox. Gear ratios determine how input speed translates into output speed and torque, which directly affects your machine’s efficiency and effectiveness. A higher gear ratio means more torque but less speed, while a lower ratio provides higher speeds at the expense of torque.

When selecting a gearbox, consider the specific requirements of your application. If you’re dealing with heavy loads, a higher gear ratio will give you the necessary torque to handle the job. Conversely, if speed is your priority, go for a lower ratio to achieve faster output.

Keep in mind that gear ratios also influence energy consumption. An optimal ratio can minimize energy loss, which is crucial for maintaining operational efficiency and reducing costs.

It’s also important to think about the flexibility of the gearbox. Some models allow for adjustable gear ratios, giving you the ability to adapt to varying operational needs. This adaptability can be a game-changer in dynamic industrial environments.

Material Durability

The durability of materials used in industrial gearboxes is crucial for ensuring reliable performance and longevity. When you’re selecting gearboxes, it’s essential to consider the materials that make up their components. High-quality materials resist wear and tear, preventing failure under heavy loads and harsh environments.

Look for gearboxes made from high-strength alloys, as these can withstand extreme stress and offer excellent fatigue resistance. Stainless steel and cast iron are popular choices, providing a good balance of strength and corrosion resistance.

If your application involves exposure to chemicals or moisture, opt for materials that can handle such conditions without degrading.

Additionally, pay attention to surface treatments like hardening or coating, which further enhance durability by reducing friction and improving resistance to corrosion.

These features not only prolong the life of the gearbox but also minimize the risk of unexpected downtime, saving you time and money in the long run.

Maintenance Requirements

Regular maintenance is vital for keeping industrial gearboxes running smoothly and efficiently.

By implementing a proactive maintenance routine, you can extend the life of your gearboxes and prevent costly downtime.

Here are three essential maintenance tasks you should prioritize:

1. Regular Lubrication: Ensure that your gearboxes are properly lubricated to reduce friction and wear.

Check the lubricant levels frequently and replace them according to the manufacturer’s recommendations.

2. Routine Inspections: Conduct regular inspections to identify any signs of wear, leaks, or unusual noises.

Early detection of issues can save you from more significant problems down the line.

3. Vibration Analysis: Use vibration analysis tools to monitor the gearbox’s condition.

This technique helps you detect misalignments, imbalance, or mechanical issues before they escalate.

Size and Weight

When selecting industrial gearboxes, size and weight play crucial roles in determining their suitability for specific applications. You need to evaluate how much space you have available and the weight restrictions of your machinery. A gearbox that’s too large can be cumbersome, impacting installation and maintenance. Conversely, a lightweight gearbox may not provide the durability needed for heavy-duty operations.

It’s essential to consider the overall dimensions of the gearbox, including its height, width, and depth. Ensure that the china gearbox manufacturer fits within the designated area without interfering with other components. Additionally, if you’re working in a dynamic environment, a lighter gearbox can facilitate easier handling and reduce wear on supporting structures.

Weight also influences the gearbox’s performance. Heavier gearboxes can typically handle greater loads and provide stability, but they may require reinforced mounts. On the other hand, lighter models are often easier to install and may reduce the overall weight of your machinery.

Ultimately, by carefully assessing size and weight, you can select an industrial gearbox that not only fits your physical constraints but also meets the demands of your application efficiently.

Conclusion

In conclusion, when choosing an industrial gearbox, keep an eye on torque capacity, gear ratios, material durability, maintenance needs, and size and weight. These features directly impact your system’s performance and reliability. By prioritizing these aspects, you can ensure that your gearbox meets your specific requirements and stands the test of time. So, take the time to evaluate each feature carefully, and you’ll make a smart investment for your machinery setup.