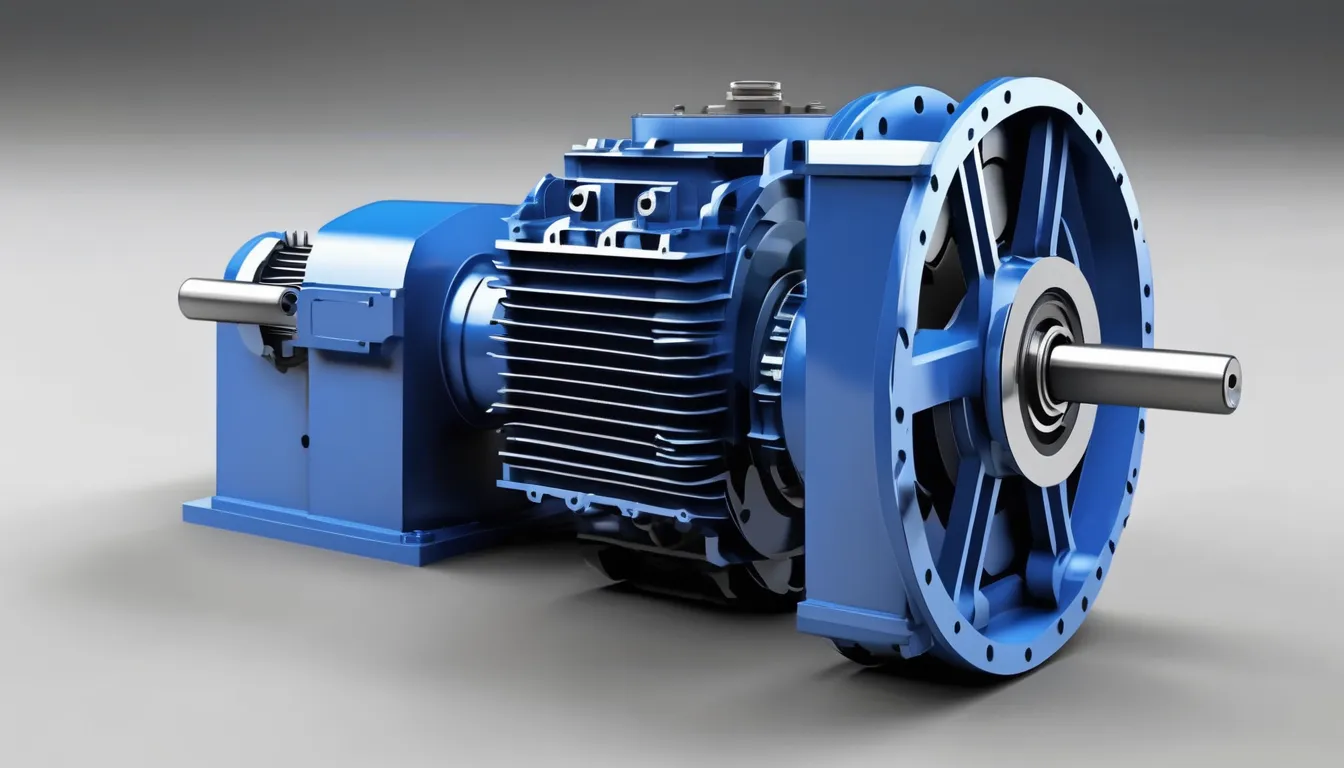

To ensure your helical gearbox operates at its best, regular maintenance is key. By following proper maintenance practices, you can enhance efficiency and extend the life of your equipment. Imagine the impact of neglecting maintenance on crucial components—wouldn’t you want to know how to prevent that? Stay tuned to discover the essential steps and strategies that can help you maximize the efficiency of your helical gearbox through routine maintenance.

Importance of Regular Maintenance

Regular maintenance is crucial for ensuring the efficiency and longevity of your helical gearbox. By conducting regular maintenance checks, you can detect potential issues early on, preventing costly repairs or replacements down the line.

Inspecting the gearbox for wear and tear, unusual noises, or leaks can help you address problems promptly before they escalate. Additionally, cleaning the gearbox to remove any debris or contaminants will contribute to its smooth operation.

Moreover, regular maintenance helps optimize the performance of your helical Helical Gearbox , ensuring that it operates at its full capacity. Lubrication levels can be checked and adjusted during maintenance to guarantee that all components are adequately lubricated, reducing friction and wear.

This proactive approach not only enhances efficiency but also extends the lifespan of your gearbox, saving you time and money in the long run.

Lubrication Best Practices

To maintain optimal efficiency in your helical gearbox, one key aspect that can’t be overlooked is adhering to proper lubrication best practices. Proper lubrication plays a crucial role in reducing friction, heat generation, and wear within the gearbox components, ultimately extending its lifespan and maximizing performance.

Here are three essential lubrication best practices to ensure your helical gearbox functions at its best:

- Use the Right Lubricant: Select a high-quality lubricant recommended by the gearbox manufacturer. Ensure it’s compatible with the gearbox materials and operating conditions to provide adequate protection and reduce friction.

- Regular Lubrication Checks: Establish a routine schedule for checking and replacing the gearbox lubricant. Monitor the lubricant levels and quality to prevent issues such as contamination or degradation over time.

- Proper Lubricant Application: Follow the manufacturer’s guidelines for the correct lubricant application method. Ensure even distribution of the lubricant throughout the gearbox to guarantee all components are adequately coated for smooth operation.

Gear Inspection Techniques

When inspecting your helical gearbox, visual gear examination and wear pattern analysis are crucial techniques to ensure optimal performance.

By visually examining the gears, you can identify any signs of wear, damage, or misalignment that may impact efficiency.

Analyzing wear patterns can provide valuable insights into potential issues and help you take proactive maintenance measures.

Visual Gear Examination

For a thorough assessment of the helical gearbox efficiency, one crucial aspect to focus on is the visual examination of the gears. When inspecting the gears visually, there are a few key things to keep in mind to ensure the gearbox’s optimal performance:

- Inspect for Wear: Look for any signs of wear such as pitting, spalling, or scoring on the gear teeth. These can indicate excessive loads or misalignment issues that need to be addressed promptly.

- Check for Proper Lubrication: Ensure that there’s adequate lubrication present on the gears. Lack of lubrication can lead to increased friction and wear, affecting the gearbox’s efficiency.

- Look for Abnormalities: Examine the gears for any unusual sounds, vibrations, or abnormalities in their operation. These can be early indicators of potential problems that might escalate if not attended to promptly.

Wear Pattern Analysis

During gear inspection, analyzing the wear patterns on the gears provides valuable insights into the gearbox’s operating conditions and potential issues. By understanding these wear patterns, you can identify if the gears are operating within normal parameters or if there are signs of abnormal wear that may indicate issues such as misalignment, overloading, or insufficient lubrication.

| Wear Pattern | Possible Cause | Action Required |

|---|---|---|

| Spalling | Excessive loading or poor lubrication | Investigate and address root cause |

| Scoring | Lack of lubrication or contamination | Check lubrication system and cleanliness |

| Pitting | Overloading or poor gear meshing | Adjust loads or improve meshing |

Alignment Adjustment Procedures

When it comes to maintaining the efficiency of helical gearboxes, precision gear alignment and proper lubrication are key factors to consider. Ensuring that gears are aligned correctly helps minimize wear and tear on the components, leading to smoother operation and increased longevity.

Additionally, using the right lubricants can reduce friction, heat, and energy losses within the gearbox system.

Precision Gear Alignment

To achieve optimal performance in your helical gearbox, ensuring precision gear alignment is crucial. Proper alignment helps reduce wear and tear on the gears, minimizes noise, and maximizes power transmission efficiency. Here are three essential steps to achieve precision gear alignment:

- Use Proper Tools: Invest in high-quality dial indicators, alignment bars, and laser alignment tools to accurately measure and adjust gear alignment. Using the right tools will ensure precise adjustments and long-lasting results.

- Follow Manufacturer Guidelines: Refer to the gearbox manufacturer’s specifications and alignment procedures. Each gearbox model may have specific alignment requirements, so following the guidelines will help you achieve the best alignment for your system.

- Perform Regular Checks: Regularly inspect the gear alignment and make adjustments as needed. Over time, vibrations and operational stresses can cause misalignment, so routine checks will help maintain optimal performance and prolong the gearbox’s lifespan.

Lubrication for Efficiency

Proper lubrication is essential for maintaining the efficiency of your helical gearbox. By ensuring that your gearbox is adequately lubricated, you can reduce friction and wear, ultimately maximizing its performance and longevity. To achieve this, start by selecting the correct lubricant recommended by the manufacturer for your specific gearbox model. Regularly check the lubricant level and quality to prevent overheating and component damage. Additionally, follow the manufacturer’s guidelines for lubrication intervals to ensure optimal gearbox operation.

When applying lubricant, make sure to clean the gearbox housing thoroughly to remove any contaminants that could compromise the effectiveness of the lubricant. Distribute the lubricant evenly across all gear teeth to guarantee smooth operation and minimize energy losses due to friction.

Periodically inspect the gearbox for any leaks or unusual noises, as these could indicate insufficient lubrication or potential issues that require immediate attention. By prioritizing proper lubrication practices, you can significantly enhance the efficiency and reliability of your helical gearbox.

Preventing Costly Downtime

Regular maintenance of your helical gearbox is crucial in preventing costly downtime. By staying proactive and implementing preventive measures, you can avoid unexpected breakdowns that could halt production and lead to financial losses.

To prevent costly downtime, consider the following:

- Scheduled Inspections: Regularly inspect your helical gearbox for signs of wear, misalignment, or lubrication issues. Identifying potential problems early on can help you address them before they escalate into major malfunctions.

- Proper Lubrication: Ensure that your gearbox is adequately lubricated according to manufacturer recommendations. Insufficient lubrication can increase friction, leading to overheating and premature wear of components.

- Training and Awareness: Invest in training for your maintenance team to ensure they understand the importance of proper gearbox care. By raising awareness about best practices and the impact of neglecting maintenance tasks, you can foster a culture of proactive maintenance that helps prevent costly downtime.

Prolonging Equipment Lifespan

Extending the lifespan of your helical gearbox can significantly benefit your operations and bottom line. By implementing proper maintenance practices and proactive measures, you can ensure that your equipment lasts longer and operates at peak efficiency.

Regularly inspecting the gearbox for signs of wear and tear, such as unusual noises or vibrations, can help you identify potential issues early on and address them before they escalate.

Additionally, following the manufacturer’s recommended maintenance schedule for lubrication and component checks is crucial in prolonging the gearbox’s lifespan. Keeping the gearbox clean and free of debris, as well as monitoring its operating temperature, can also contribute to its longevity.

Investing in high-quality lubricants and replacement parts when necessary can prevent premature wear and extend the overall lifespan of the gearbox.

Frequently Asked Questions

What Are the Common Signs of Gearbox Wear and Tear?

If you notice unusual noises, vibrations, or leaks in your gearbox, it’s time to take action. Regular maintenance can help identify and address wear and tear early, ensuring optimal performance and longevity.

Can Using a Different Lubricant Affect Gearbox Performance?

Using a different lubricant can significantly impact gearbox performance. It may alter friction levels, viscosity, and overall lubrication effectiveness. Ensure you follow manufacturer recommendations to maintain optimal efficiency and prevent potential damage to your gearbox.

How Often Should Gearbox Alignment Be Checked?

You should check gearbox alignment regularly to ensure optimal performance. Misalignment can lead to increased wear and decreased efficiency. By scheduling periodic checks, you can prevent potential issues and maintain the gearbox’s functionality.

Are There Specific Tools Required for Gear Inspection?

You don’t need specialized tools for gear inspection. A visual check for wear, debris, and proper alignment can be done with basic tools like calipers, micrometers, and inspection mirrors. Regular maintenance helps spot issues early.

What Are the Consequences of Neglecting Gearbox Maintenance?

Neglecting gearbox maintenance leads to reduced efficiency, increased wear, and potential breakdowns. Regular upkeep ensures optimal performance, longer lifespan, and cost savings. Take care of your gearbox to avoid costly repairs and downtime.

Conclusion

In conclusion, by regularly maintaining your helical gearbox through proper lubrication, gear inspections, and alignment adjustments, you can maximize efficiency, prevent costly downtime, and extend the lifespan of your equipment. Stay proactive in your maintenance efforts to ensure optimal performance and avoid unexpected breakdowns. Remember, investing time and resources in maintenance now can save you time and money in the long run. Keep your helical gearbox running smoothly with regular maintenance checks.