When you examine the history of gearbox technology, you’ll find it’s a fascinating journey that begins with ancient civilizations crafting wooden gears and culminates in today’s advanced systems. The evolution from simple mechanisms to complex designs has shaped not only machinery but also the very landscape of transportation. As you explore the pivotal moments and key innovations, you’ll uncover how these developments have influenced modern automotive advancements. But what lies ahead in the future of gearbox technology, and how might it transform our understanding of efficiency and performance?

Ancient Origins of Gear Technology

Throughout history, ancient civilizations have harnessed the power of gears to transform motion and improve machinery. You might be surprised to learn that the use of gears dates back thousands of years, with evidence of their existence found in ancient Mesopotamia and Greece. The earliest gears were made from wood and later from metal, showcasing the ingenuity of these cultures.

As you delve deeper, you’ll discover that the Antikythera mechanism, an ancient Greek device, is often considered one of the first analog computers. It used a series of gears to predict astronomical positions and eclipses, highlighting the complexity and sophistication of gear technology in that era.

In China, gears played a significant role in the development of water-powered machinery, such as the watermill, which harnessed energy for various tasks. The gears enabled these machines to operate efficiently, showing that even in ancient times, understanding mechanics was crucial for innovation.

You can see how these early advancements laid the groundwork for future developments. By appreciating the ancient origins of gear technology, you gain insight into how foundational these innovations were for the evolution of machinery and engineering.

The Rise of Mechanical Innovation

The Industrial Revolution marked a pivotal moment in the rise of mechanical innovation, transforming societies and economies across the globe. You can see how this era spurred advancements in machinery that dramatically improved productivity. Instead of relying solely on human or animal power, you began to witness the introduction of steam engines and waterwheels, which paved the way for more complex mechanical systems.

As factories emerged, the demand for efficient and dependable gear systems skyrocketed. You’d find gears at the heart of various machines, enabling them to function smoothly and efficiently. This wave of innovation didn’t just enhance manufacturing processes; it changed how people viewed work and industry. Suddenly, there was a growing appreciation for precision engineering and the potential of mechanical devices to perform tasks previously thought impossible.

Moreover, you can appreciate how this period fostered a culture of experimentation and invention. Inventors and engineers collaborated, pushing the boundaries of what machinery could achieve.

The rise of mechanical innovation during this time set the foundation for future developments, leading to the sophisticated gearbox technologies we rely on today.

Key Innovations in Gear Design

Innovations in gear design have revolutionized how machines operate, making them more efficient and reliable. You mightn’t realize it, but these advancements have a profound impact on everyday life, enhancing performance and durability across various industries.

From manufacturing to robotics, each innovation brings you closer to a world where machines work seamlessly, allowing for greater productivity and safety.

Here are some key innovations in gear design that truly stand out:

- Helical Gears: They offer smoother and quieter operation, reducing noise pollution in your environment.

- Planetary Gear Sets: These compact designs maximize torque and efficiency, making your machines lighter and more powerful.

- Variable-Geometry Gears: They adapt to changing loads, ensuring your systems remain responsive and reliable.

- Composite Materials: Using lightweight materials increases fuel efficiency and decreases wear, leading to longer-lasting equipment.

- 3D Printing: This technology allows for custom gear shapes, enabling innovation tailored to specific applications.

These advancements not only enhance performance but also inspire creativity, pushing the boundaries of what machines can achieve.

Impact on Automotive Advancements

Advancements in gear technology have significantly influenced automotive engineering, propelling the industry toward greater efficiency and performance. You can see this impact in the transition from traditional manual transmissions to sophisticated automatic and dual-clutch systems. These modern gearboxes enable smoother gear changes, enhancing driving comfort while optimizing engine power delivery.

Moreover, innovations like continuously variable transmissions (CVTs) allow for an infinite number of gear ratios, which means you can enjoy improved fuel efficiency and reduced emissions. This shift not only benefits your wallet at the pump but also aligns with global environmental standards.

The integration of electronic controls in gear systems has taken performance to another level. With real-time data processing, these systems adapt to your driving style, ensuring that gear shifts are both timely and precise. This responsiveness enhances the overall driving experience, making vehicles more enjoyable and easier to handle.

As manufacturers continue to refine gearbox technologies, you’ll likely notice the direct correlation between these advancements and the overall performance of modern vehicles. The evolution of gear technology has truly shaped the automotive landscape, paving the way for innovations that meet today’s demands for efficiency and reliability.

Future Trends in Gearbox Development

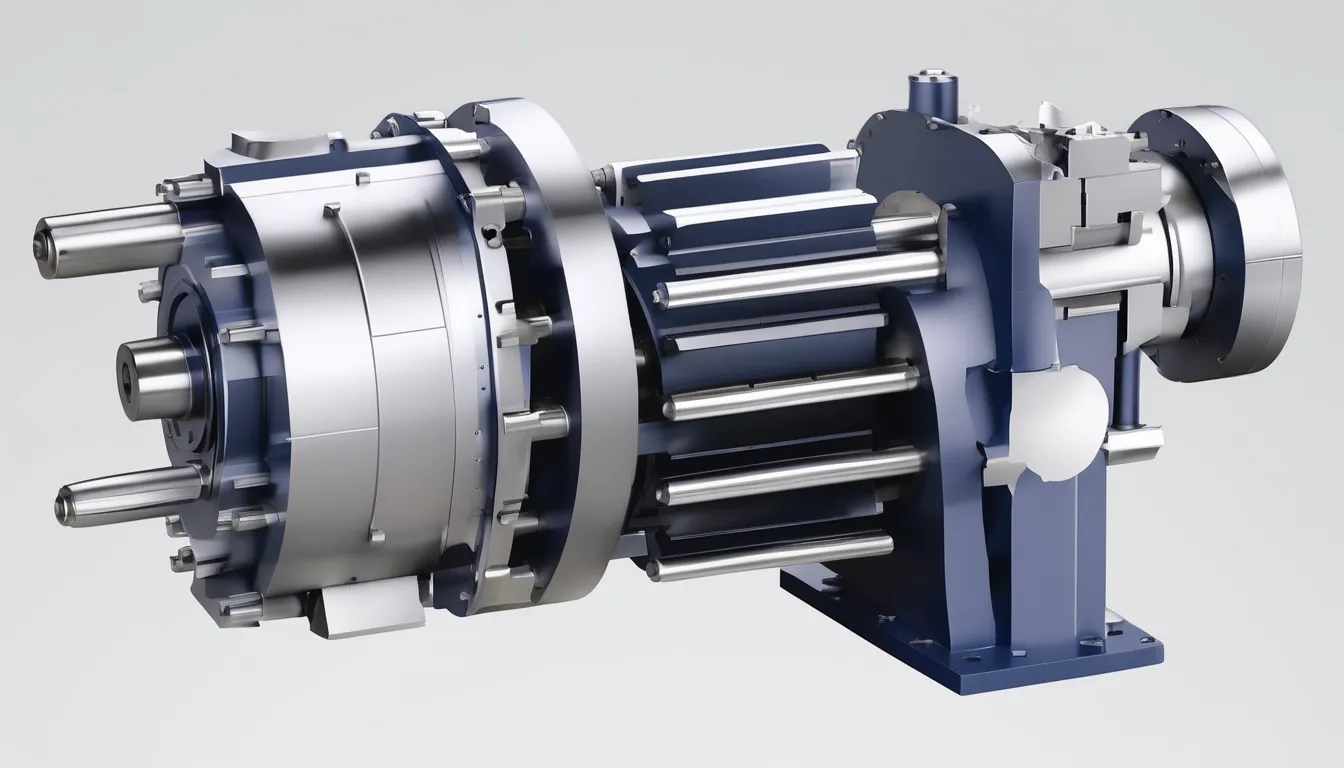

Gearbox development is on the brink of a technological revolution, driven by emerging trends in electric and hybrid vehicles. As you explore the future of gearboxes, you’ll notice a shift towards more efficient, compact designs. Manufacturers are prioritizing lightweight materials and advanced manufacturing techniques, ensuring that gearboxes can handle higher torque while reducing weight.

In this rapidly evolving landscape, you can expect:

- Increased efficiency: New designs will minimize energy loss, maximizing vehicle performance and range.

- Smart technology integration: Gearboxes will incorporate real-time monitoring systems, improving maintenance and operational efficiency.

- Sustainability focus: Manufacturers are committing to eco-friendly materials, reducing their environmental footprint.

- Adaptive systems: Future gearboxes will adjust automatically to driving conditions, enhancing safety and performance.

- Enhanced user experience: With smoother shifts and reduced noise, driving will become more enjoyable and comfortable.

As these trends unfold, you’ll find that the future of Industrial Gear Drive technology not only promises better performance but also an exciting journey towards more sustainable and innovative solutions in the automotive world.

Stay tuned, because the best is yet to come!

Conclusion

In exploring the history of gearbox technology, you’ve uncovered the incredible journey from ancient gears to today’s smart systems. Each innovation has shaped how machines operate, especially in the automotive world. As you look to the future, it’s clear that gear technology will continue evolving, pushing boundaries and enhancing efficiency. Embracing these advancements not only promises improved performance but also paves the way for sustainable solutions in transportation. Exciting times lie ahead in gearbox development!