As you consider the future of industrial reducers, think about how advancements in smart technology are transforming the landscape. You’re likely aware that integrating IoT and machine learning can significantly boost performance and energy efficiency. But what about the implications of compact designs and sustainable practices? These innovations not only promise better space utilization but also align with the growing demand for eco-friendly solutions. The question remains: how will these trends shape the industry in the coming years and what challenges might arise in this transition?

Advancements in Smart Technology

In today’s rapidly evolving industrial landscape, smart technology is revolutionizing the way reducers operate. You’ll find that advanced sensors and monitoring systems are now integrated into these devices, allowing for real-time data collection and analysis. This means you can track performance metrics, detect anomalies, and predict maintenance needs before they become critical issues.

Moreover, with the rise of the Internet of Things (IoT), you’re able to connect your reducers to broader networks, enabling seamless communication across various systems. This connectivity not only enhances operational efficiency but also empowers you to make informed decisions based on accurate, current data.

Another significant advancement is the incorporation of machine learning algorithms. These algorithms can analyze historical performance data, helping you optimize reducer settings for specific applications. As a result, you can improve energy efficiency and extend the lifespan of your equipment.

Ultimately, embracing these advancements in smart technology not only simplifies your operational processes but also drives significant cost savings. By leveraging these innovations, you can transform how your industrial operations function, ensuring you’re always one step ahead in a competitive marketplace.

Compact Design Innovations

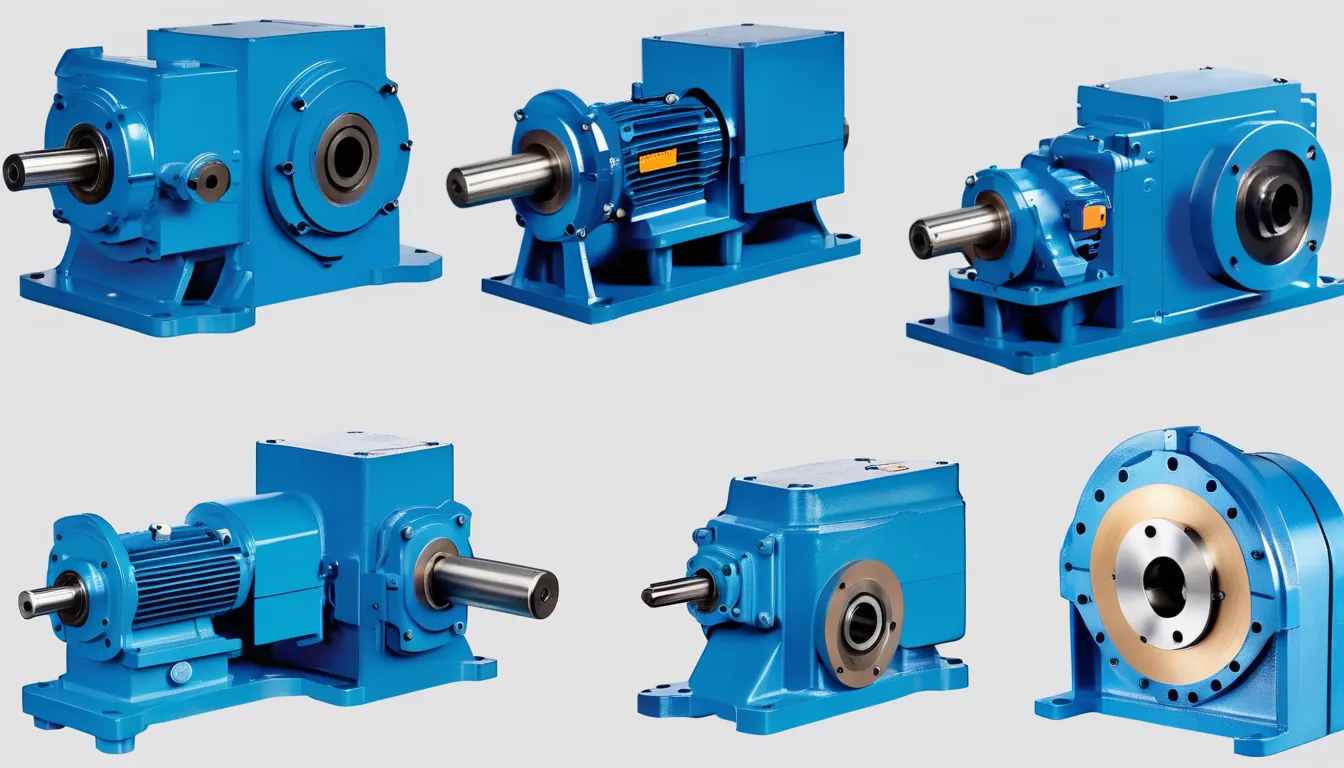

With a focus on efficiency and space optimization, compact design innovations in industrial Reducer Manufacturer s are transforming how you approach equipment installation and layout.

These advancements allow you to maximize your available space while maintaining or even enhancing performance. By integrating smaller, lighter components without sacrificing power, manufacturers are making it easier for you to fit reducers into tight spaces or to streamline machinery design.

You’ll also find that these compact designs often reduce weight, which can lead to lower transportation costs and easier handling during installation.

The smaller footprint means you can free up valuable floor space for other essential equipment or processes, improving overall operational efficiency.

Moreover, the modular nature of many compact reducers enables you to customize your setup according to specific needs.

This flexibility allows for faster upgrades and easier maintenance, reducing downtime and boosting productivity.

Incorporating these innovations not only enhances your machinery’s performance but also contributes to a more organized and efficient workspace.

As you explore options, keep an eye out for these compact designs that can revolutionize your operations and position you for future growth.

Sustainable Materials and Practices

Sustainable materials and practices are reshaping the landscape of industrial reducers, making them not just efficient but also environmentally friendly. You’ll find that manufacturers are increasingly opting for recycled and biodegradable materials, reducing the environmental footprint of their products.

By embracing sustainable practices, companies can lower energy consumption during production, which translates to a smaller carbon footprint.

When sourcing materials, look for suppliers who prioritize eco-friendly options. You can also consider the lifecycle of the reducer itself; choosing products designed for easy disassembly can enhance recyclability. This approach not only benefits the planet but can also lead to cost savings in the long run.

Moreover, many companies are adopting lean manufacturing techniques, minimizing waste during production. This method ensures that fewer resources are consumed, making a significant difference in sustainability.

Educating your team about these practices can foster a culture of environmental responsibility, benefitting both your organization and the planet.

As you plan for the future, think about how you can integrate these sustainable materials and practices into your operations. By doing so, you’ll contribute to a greener industry while enhancing your brand’s reputation.

Enhanced Performance Metrics

Enhanced performance metrics are revolutionizing how industrial reducers are evaluated and optimized. You’ll find that these metrics enable you to assess efficiency, durability, and overall effectiveness more accurately than ever. By analyzing specific performance indicators, you can pinpoint areas for improvement and drive operational excellence.

| Performance Metric | Importance |

|---|---|

| Efficiency Ratio | Measures energy consumption |

| Load Capacity | Indicates maximum stress |

| Response Time | Assesses speed of operation |

| Maintenance Frequency | Determines upkeep needs |

| Lifespan | Evaluates durability |

These metrics allow you to make data-driven decisions, enhancing productivity while reducing downtime. You can also gain insights into how different materials and technologies impact performance, leading to better choices in design and implementation. As you adopt these enhanced metrics, you’ll not only improve your current systems but also set a foundation for future innovations. Understanding these performance indicators is key to maintaining a competitive edge in a rapidly evolving industry. By focusing on enhanced performance metrics, you’re ensuring that your industrial reducers work efficiently and effectively, ultimately contributing to your organization’s success.

Future Trends in Automation

Automation is rapidly transforming the industrial landscape, and you should stay informed about the key trends shaping its future.

One major trend is the integration of artificial intelligence (AI) into automation processes. AI enhances decision-making and predictive maintenance, reducing downtime and improving efficiency. By leveraging AI, you can optimize operations and minimize costs.

Another trend is the rise of collaborative robots, or cobots. These machines work alongside human operators, increasing productivity while maintaining safety. You’ll find that incorporating cobots into your workflow allows for greater flexibility and adaptability in various tasks.

Moreover, the Internet of Things (IoT) is playing a crucial role in automation. With IoT devices, you can monitor equipment in real-time, collect data, and analyze performance metrics. This connectivity enables more informed decision-making and streamlines processes.

Lastly, don’t overlook the importance of cybersecurity in automation. As systems become more interconnected, protecting sensitive data from cyber threats is essential. You’ll need to implement robust security measures to safeguard your operations.

Conclusion

In conclusion, the future of industrial reducers is exciting and full of potential. By embracing smart technology, compact designs, and sustainable practices, you can enhance efficiency while reducing costs. You’ll witness firsthand how these innovations lead to improved performance and adaptability in your operations. As the industry evolves, staying ahead of these trends will empower you to optimize your processes and contribute to a greener future. Embrace these changes, and watch your business thrive in the automation landscape.