When it comes to running a successful kitchen, you know that food equipment repair parts play a crucial role in keeping your appliances in top shape. Ignoring the quality and condition of these components can lead to unexpected breakdowns and costly downtime. By understanding the importance of reliable parts, you can make informed decisions that enhance your kitchen’s efficiency. But what specific issues should you be aware of, and how can you ensure you’re choosing the right components? Let’s explore these vital aspects that could make all the difference in your operations.

Importance of Quality Parts

When it comes to food equipment repair, there’s no denying that quality parts matter. You wouldn’t want to compromise the performance of your equipment with subpar replacements. Using high-quality parts ensures that your machines run efficiently and reliably, which can save you time and money in the long run.

Think about it: inferior parts can lead to frequent breakdowns and costly repairs. You might find yourself in a cycle of replacing parts over and over, which disrupts your operations and frustrates your staff. Instead, investing in quality components means you’re making a long-term choice for your business.

Quality parts are manufactured to meet or exceed industry standards, ensuring compatibility and durability. This not only enhances the longevity of your equipment but also maximizes its performance. When you choose reliable parts, you’re safeguarding your investment and maintaining the integrity of your food service operations.

In a fast-paced environment, you need your equipment to perform at its best. So, don’t underestimate the importance of quality parts; they’re the backbone of successful food equipment repair and maintenance.

Invest wisely, and you’ll reap the rewards.

Common Equipment Issues

Even with high-quality parts, equipment can still face issues that disrupt your operations. It’s frustrating when machines you rely on start malfunctioning, impacting productivity and service. Understanding common equipment issues can help you identify problems early and take action quickly.

Here’s a quick overview of some typical equipment issues you might encounter:

| Issue | Symptoms |

|---|---|

| Overheating | Equipment shuts down or malfunctions after running for a while. |

| Unusual Noises | Grinding, squeaking, or rattling sounds during operation. |

| Leaks | Water pooling around equipment or dripping from connections. |

| Inconsistent Performance | Fluctuating temperatures or uneven cooking results. |

Types of Repair Parts

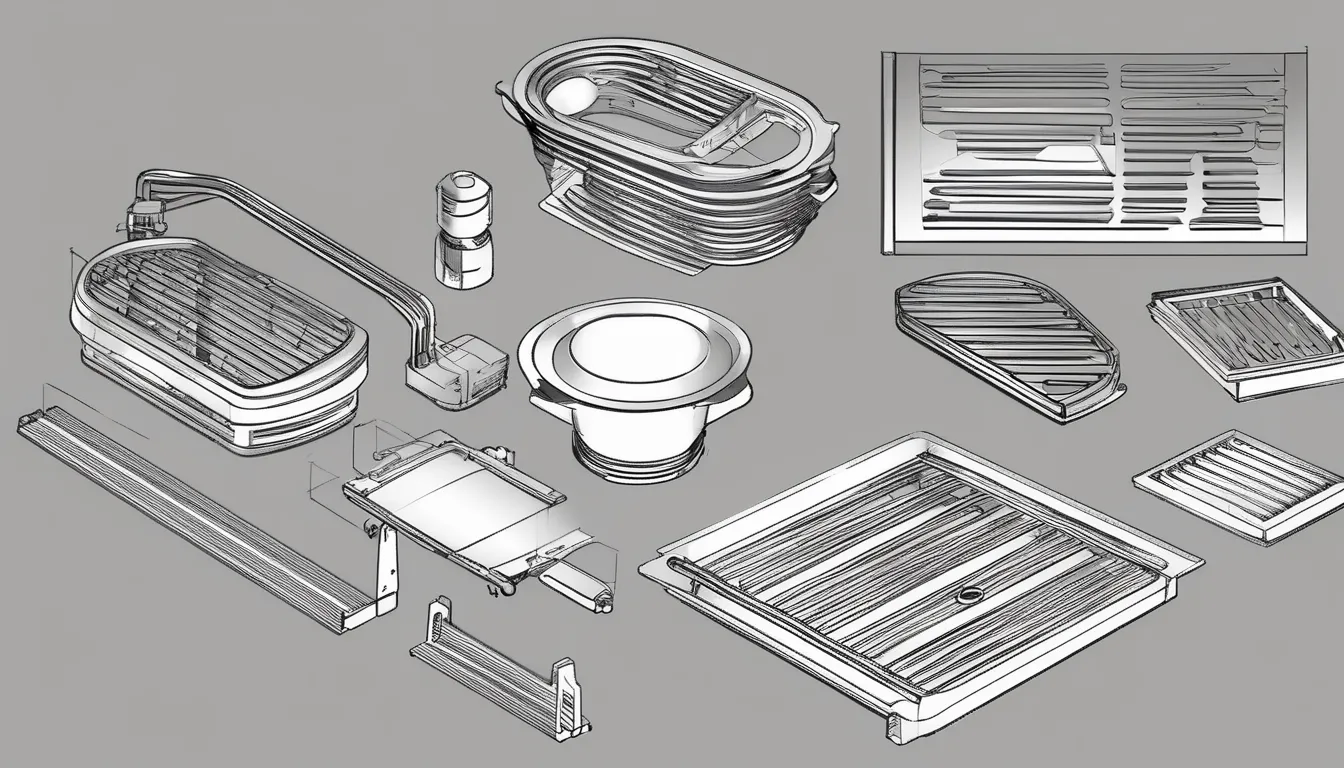

Identifying the right types of repair parts can make all the difference in getting your equipment back up and running smoothly.

You’ll encounter various parts depending on your equipment type, such as heating elements, motors, and seals. Each of these serves a critical function, and knowing what you need is essential.

Heating elements are vital for ovens and fryers; they ensure your food cooks evenly. If you notice your equipment isn’t reaching the correct temperature, this could be the part you need to replace.

Motors, found in mixers and dishwashers, drive the mechanical components. If your machine is struggling to operate or making unusual noises, consider checking the motor.

Seals and gaskets are often overlooked but are crucial for preventing leaks in equipment like refrigerators and dishwashers. If you notice condensation or water pooling, it’s time to examine these parts.

Other repair parts include filters for ventilation systems and control panels for managing settings.

Choosing the Right Supplier

Selecting the right supplier for your repair parts is crucial to ensuring your equipment operates efficiently. You want to find a provider that not only stocks the parts you need but also offers quality and reliability. Here are some key factors to consider when choosing a supplier:

| Criteria | Importance |

|---|---|

| Product Quality | Ensures longevity and performance |

| Availability | Reduces downtime during repairs |

| Customer Support | Assists with questions and concerns |

| Pricing | Fits your budget without sacrificing quality |

| Delivery Times | Keeps your operations running smoothly |

Evaluate potential suppliers based on these criteria. Start by checking their reputation and reading reviews. You might even ask colleagues for recommendations. Once you’ve narrowed down your options, it’s wise to request quotes and compare them to ensure you’re getting the best deal.

Maintenance Tips for Longevity

How can you ensure your food equipment lasts longer and operates efficiently? Regular maintenance is key.

Start by creating a cleaning schedule tailored to your equipment’s needs. Wipe down surfaces daily and deep clean weekly to prevent buildup that can affect performance.

Next, check moving parts for wear and tear. Lubricate hinges, gears, and other components as needed to keep everything running smoothly.

Don’t forget to inspect electrical connections; loose wires can lead to malfunctions.

You should also keep an eye on temperatures. Make sure your refrigeration units are functioning optimally, as temperature fluctuations can spoil food and strain your equipment.

Another important tip is to stay organized. Keep a log of repairs and maintenance tasks. This helps you track what’s been done and when it’s time meat grinder repair parts the next service.

Conclusion

To keep your commercial kitchen running smoothly, investing in quality food equipment repair parts is crucial. By addressing common equipment issues and using the right components, you can enhance reliability and extend the life of your appliances. Don’t forget to choose a trusted supplier and follow maintenance tips to prevent breakdowns. With proper care and timely replacements, you’ll not only safeguard your investments but also ensure your food service operations remain efficient and successful.